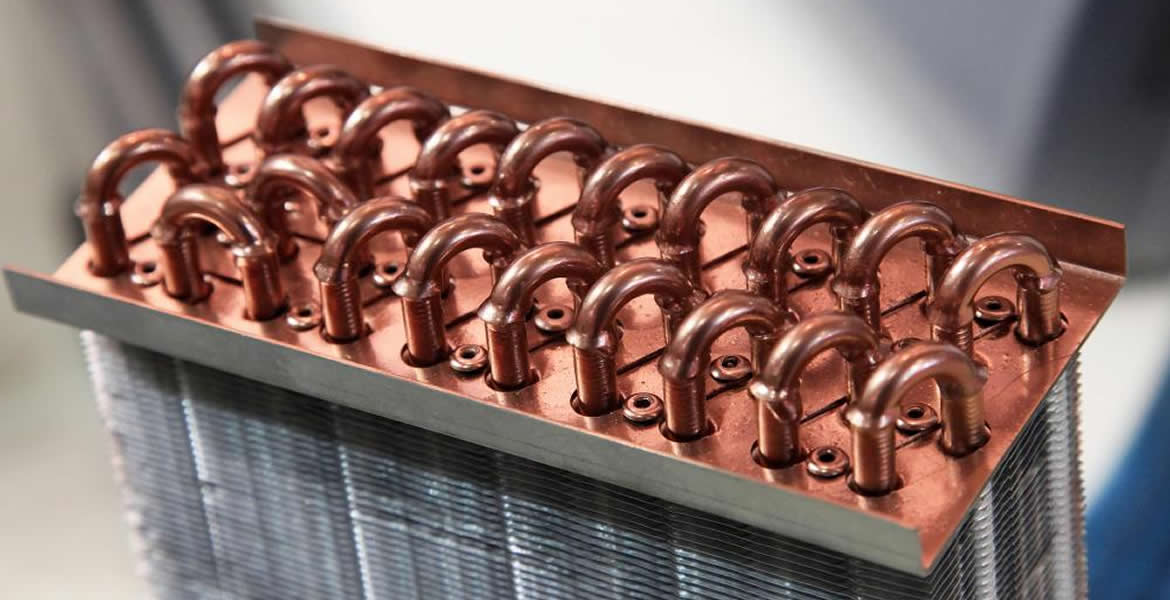

Graphene is also known as king of new materials or black gold, is a thinnest and hardest new nanomaterial with most conductive and thermal conductivity found so far. With the development of modern science and industrial technology, the requirement to graphene production is also higher and higher. Graphene can be prepared by ultrasonic dispersion at lower cost and in large quantities, and further to realize broad commercialized applications such as photo-sensitive components, new energy, sensors, paint and coatings, electrodes, batteries, transistors, flexible displays, solar energy, ultra-light materials, composite materials, sea water desalination, etc.