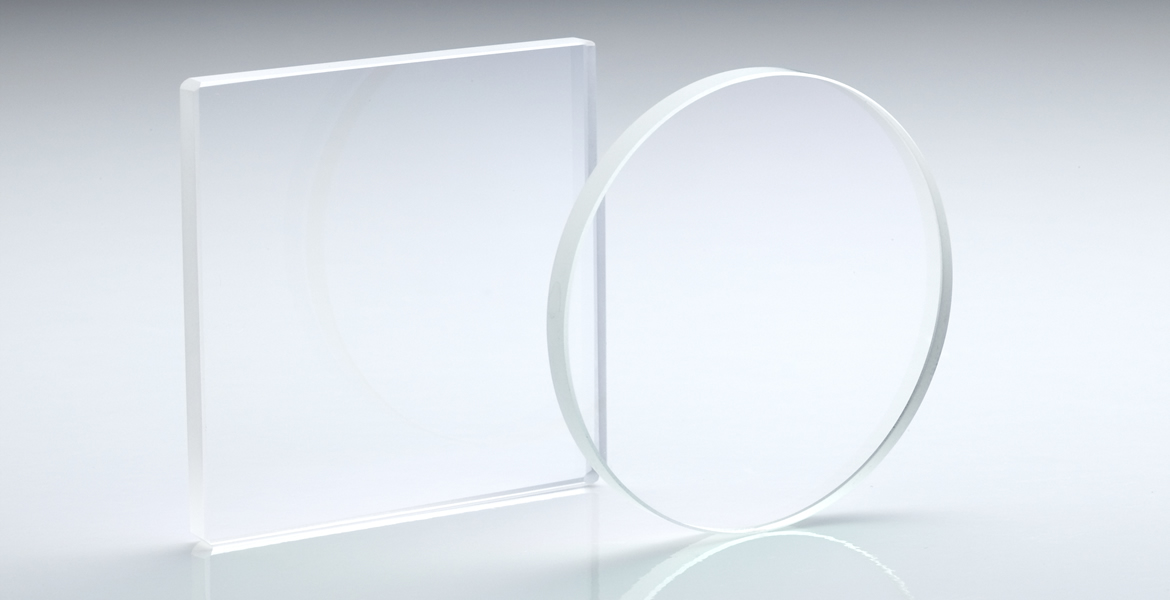

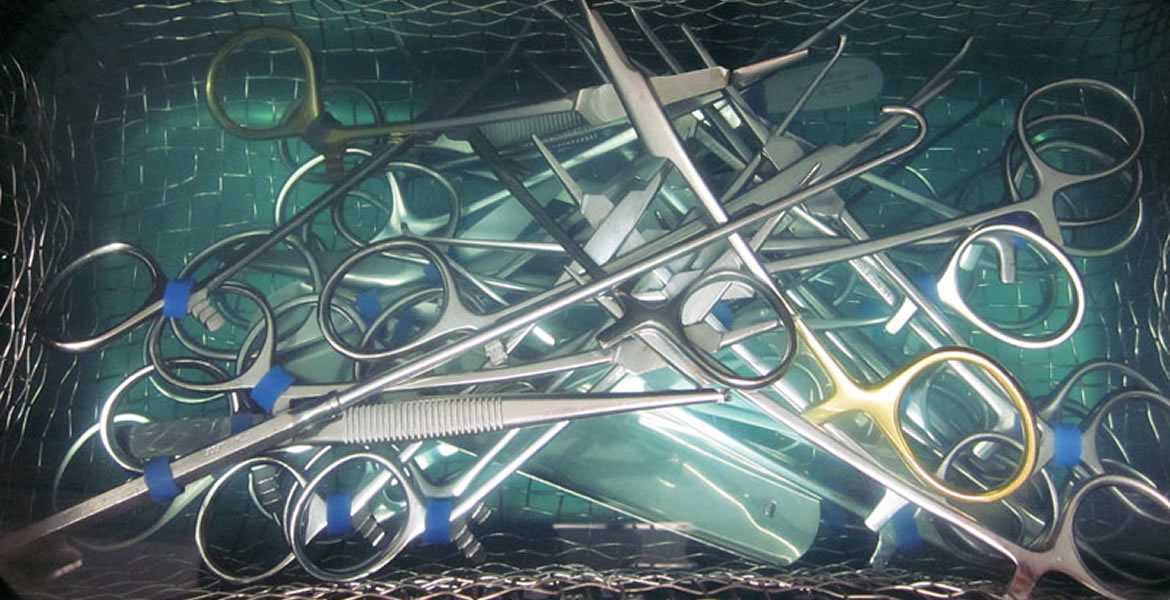

Ceramic disc filter is a kind of effective energy saving equipment which is designed to separate liquids from solids, broadly used in mineral processing technology. Ceramic filter plate is the key part of ceramic disc filter, composite porous ceramic is used as a new filter material, the fouling of the filter plate must be cleaned timely to maximize the production efficiency of ceramic filters. Ultrasonic cleaning box has incomparable cleaning effect which cannot be reached by other cleaning methods no matter common cleaning equipment or solvent. Ultrasonic cleaning and pickling compose the uniting cleaning system and fully ensure the patency of ceramic filter plates and high efficiency of filtration.